Coming from a clinical background, em-tec’s technology is perfectly suited to the strict hygienic requirements of the pharmaceutical and bioprocessing sector. Whether for the laboratory environment or fully automated industrial bioprocesses, em-tec offer products and systems for the measurement of flow in flexible tubing with absolutely no product contact – thus eliminating the risk of cross contamination. The technology is perfect for use with today’s single-use systems and fluid paths and is compatible with most tubing types from 1/4″ OD up to 1 3/16″ OD.

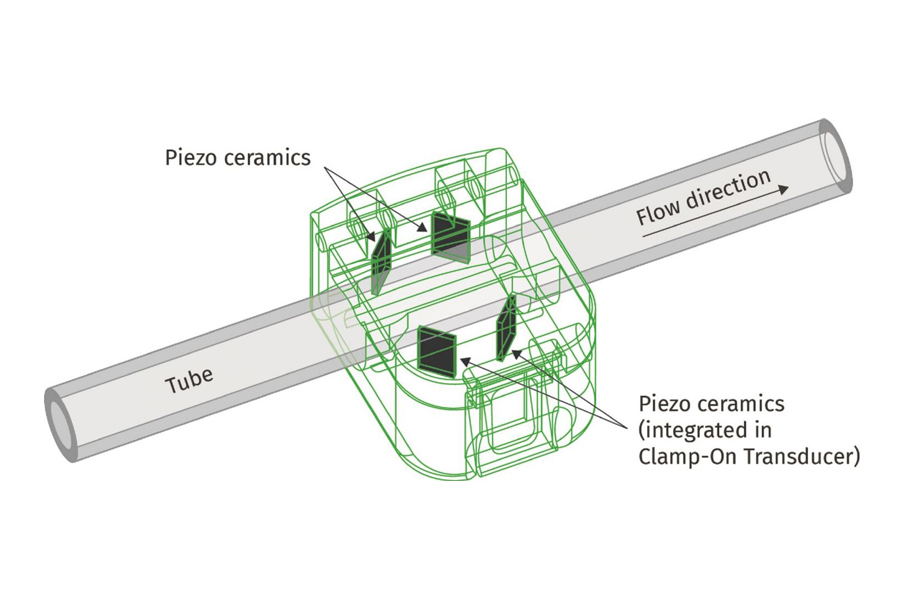

设备的工作原理是超sonic transit-time method, the flow measurement is non-invasive, meaning without direct contact to the medium

When sending ultrasonic sound signals through the measuring section, thetransit time differencedepends on the flow direction of the medium:

- If the ultrasonic sound signals are sent along the flow direction, the downstream signal needs less time.

- If the ultrasonic sound signals are sent against the flow direction, the upstream signal needs more time.

- The evaluation of the received ultrasonic signals is based on the upstream and the downstream measuring section.

Consequently, thetransit time differenceis measured for every pulse. The difference between upstream and downstream measurements is proportional to the volumetric flow rate.

Flow measurement solutions on alaboratory scale

在生物技术领域,上游过程s is among the first steps towards the final product. The aim is to grow the biomolecules required until they reach the required density and can be harvested. For small scale productions, i.e. when a small amount of biomolecules is needed, this step usually takes place in a laboratory.

For lab scale processes, our BioProTT™ FlowTrack plus and range of BioProTT™ Clamp-On Transducers offer a non-invasive flow measurement solution where the flow values are accessible and displayed in real-time for more safety and control throughout your process.

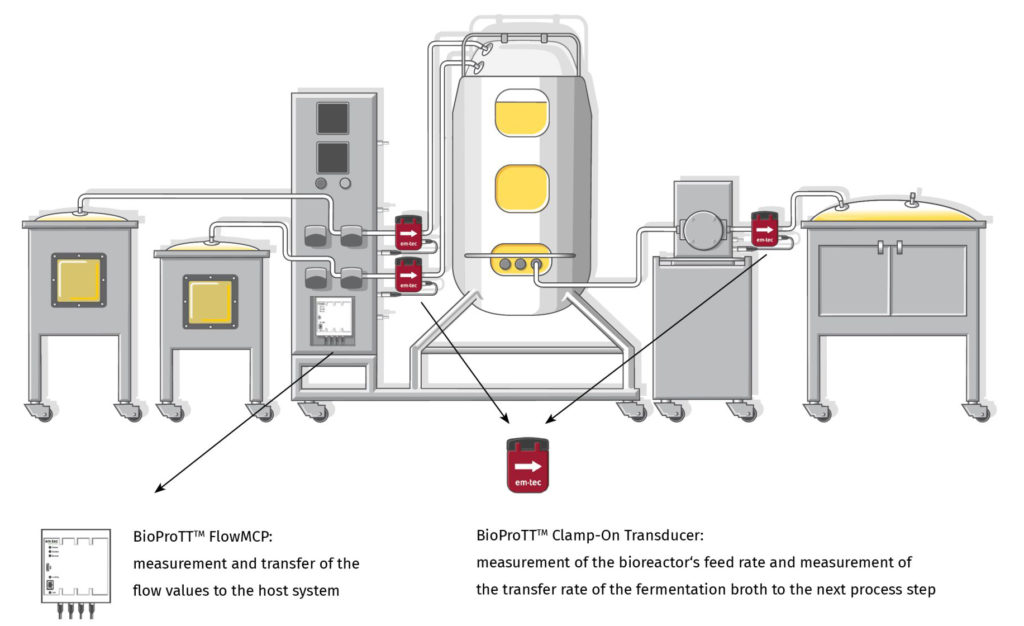

Flow measurement solutions for industrial applications

At the larger, industrial scale, the general process is similar to laboratory scale — biomolecules are grown from cell lines, usually bacterial or mammalian, and then transferred to the next process step.

At industrial scale flow measurement is achieved with a BioProTT™ FlowMCP in combination with a BioProTT™ Clamp-On Transducer. Flow sensors are available in 16 different sizes and the BioProTT™ FlowMCP can measure up to eight flow channels simultaneously, depending on the variant. Together, the system is ideally suited for GMP-oriented processes and fulfils strict hygienic requirements making it a great addition to your application.

Flow measurement solutions for downstream processing

Following a successful fermentation process, biomolecules are transferred to the next stage, where the downstream processing takes place. Here, the biosynthetic product is recovered and purified. To isolate the final product, the purification is a multi-step process involving, for example, cross-flow filtration and chromatography before the filling can take place.

For downstream process (DSP) the integration of the BioProTT™ Flow Measurement System consisting of the BioProTT™ FlowMCP and the BioProTT™ Clamp-On Transducers makes it possible to measure and control the flow rates during each process step, adding more safety to your application and ensuring the highest possible quality of the final product. .