ABER’s pioneering work in the development and use of dielectric instrumentation to monitor biomass, by measuring cell membrane capacitance and media conductivity, has regularly set new standards. In the biotech market, our current FUTURA range is seen as the benchmark in determining live cell concentration online in bioreactors.

The ABER product ranges

Principle of ABER’s Cell capacitance Technology

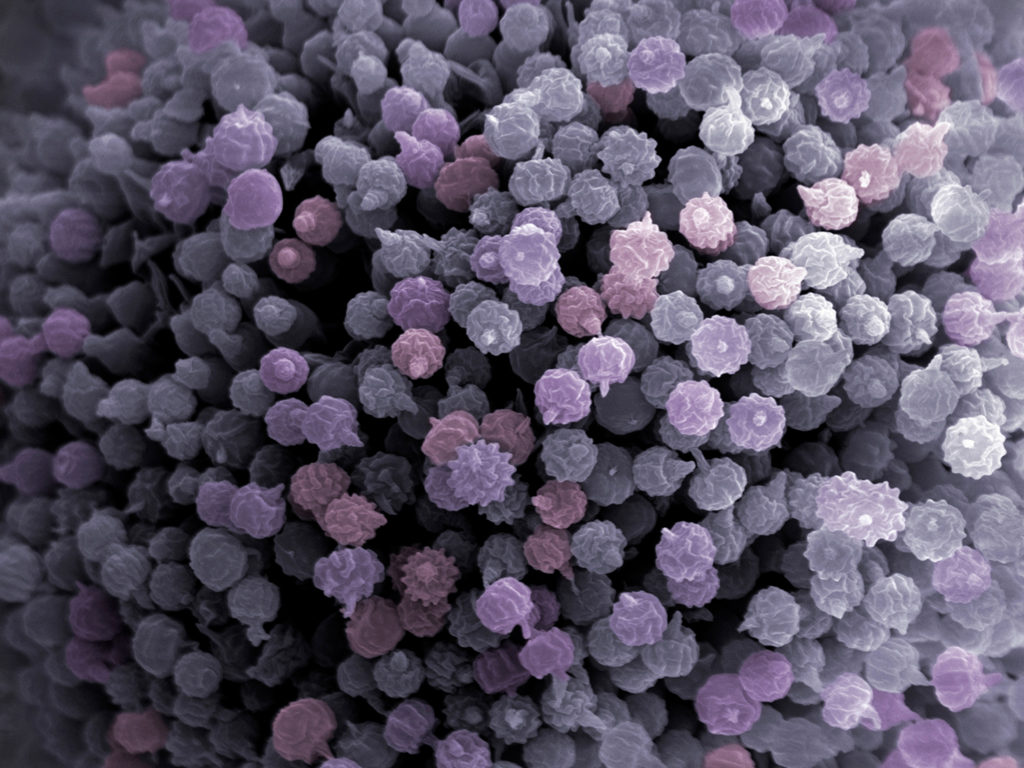

Cells with intact plasma membranes in a fermenter can be considered to act as tiny capacitors under the influence of an electric field.

The non-conducting nature of the plasma membrane allows a build up of charge. The resulting capacitance can be measured: it is dependant upon the cell type and is directly proportional to the membrane bound volume of these viable cells.

Aber’s technology converts capacitance into a live biomass reading, typically cells/ml or g/l. However, other units can be derived from the raw capacitance measurements; these may be more relevant to the chosen application.

FUTURA also measures the Conductivity of the medium, in millisiemens per centimetre (mS/cm). Conductivity is not used to measure biomass but is indicative of the production or utilisation of ions by the cell suspension, e.g. pH control and other fermentation processes.

Cell Membrane Capacitance Measurement – View on the Aber Website

WHO TO CONTACT

A measured approach to optimising performance, experience and outcomes

Aber Instruments’ technology can be applied to in both R&D and manufacturing processes to monitor:

Cell culture process development and manufacturing

Aber Instruments’ technology can be applied to in both R&D and manufacturing processes to monitor:

- Suspension cell

- Micro-carrier culture and packed beds

- Cell culture – Manufacturing

- Controlling constant cell concentrations

Microbial applications

And, our technology is equally successfully deployed in microbial applications to measure:

- Bacterial fermentations

- High density yeast fermentations

- Pichia fermentations

- Mycelial fermentations

我们的技术提供了独特的机会eal time, accurate measurement and control of biomass concentrations in bioreactors at both laboratory and industrial scale., bringing significant scientific, operational and commercial benefits in terms of cost reduction and improved product quality.

Features

- Fully automated ‘plug and play’ solutions for rapid cell expansion

- Quick and simple process monitoring

- Automated process control and modelling

- Automated substrate feed strategies

- Harvest point determination

- Optional time of infection for viral production

Benefits

- Lower risk of contamination

- Reduced risk of unrepresentative samples (due minimising the requirement for manual handling)

- Decreased labour and lab costs for offline analysis